PLC Timer Programming Tutorial: Mastering On‑Delay Timers (TON)

Learn how on‑delay timers (TON) work in PLC ladder logic, how to set presets and accumulated values, and explore real‑world applications such as conveyor startup delays. This beginner’s guide from Bob Teaches Tech covers every detail to help you master PLC timer programming.

On‑delay timers, commonly known as TON timers, are one of the most frequently searched and essential functions in PLC programming. Whether you are a beginner or looking to refresh your skills, understanding how TON timers work is crucial for designing reliable automation systems. In this comprehensive tutorial, we will:

- Explain what on‑delay timers are and why they’re important

- Walk through the configuration of a TON timer in ladder logic

- Explore a practical, real‑world application (e.g., conveyor startup delay)

- Share expert troubleshooting tips and best practices

What Are On‑Delay Timers?

Definition & Purpose

An on‑delay timer (TON) in a PLC delays the activation of an output until a preset period has elapsed after the input signal goes high. This means that when a process requires a delay to ensure stability or to allow time for safety checks, a TON timer is used.

How It Works

- Input Activation: When the designated input (e.g., a start button) is activated, the TON timer begins counting.

- Accumulated Time (ACC): The timer starts at zero and accumulates time.

- Preset Value (PRE): Once the accumulated time equals the preset value, the timer’s done bit (DN) goes high, which in turn triggers the desired output.

- Status Bits:

- .EN is set when the timer is enabled.

- .TT indicates the timer is actively counting.

- .DN confirms that the timer has completed the delay.

This delay is critical in ensuring that processes do not start prematurely and that all necessary conditions are met before moving on to the next step.

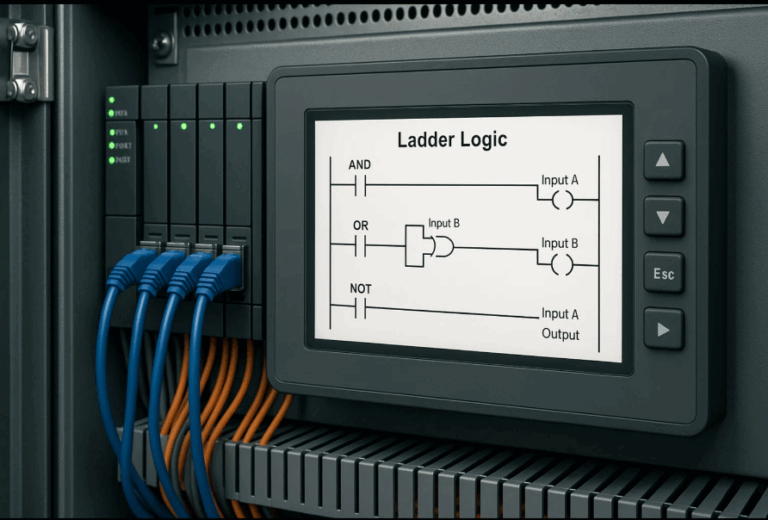

Configuring a TON Timer in Ladder Logic

Step‑by‑Step Setup

-

Timer Tag (File Name):

Assign a unique tag (e.g.,Timer1) to the timer. This tag is used to reference the timer’s parameters within your PLC program. -

Setting the Preset Value (PRE):

The preset value defines how long the timer will delay before activating the output. For example, if your PLC uses a time base of 0.1 seconds, setting the preset to 100 will create a 10‑second delay. -

Accumulated Value (ACC):

Initially, the accumulated value is 0. It increases until it reaches the preset value, at which point the timer is considered complete. -

Monitoring the Status Bits:

- .EN (Enable Bit): Turns high when the timer is activated.

- .TT (Timing Bit): Remains high while the timer is counting.

- .DN (Done Bit): Goes high when the timer’s accumulated value equals the preset value.

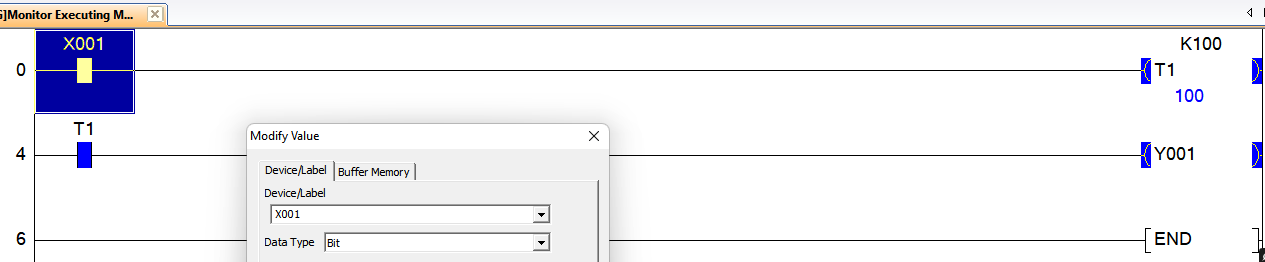

Example Ladder Logic Diagram

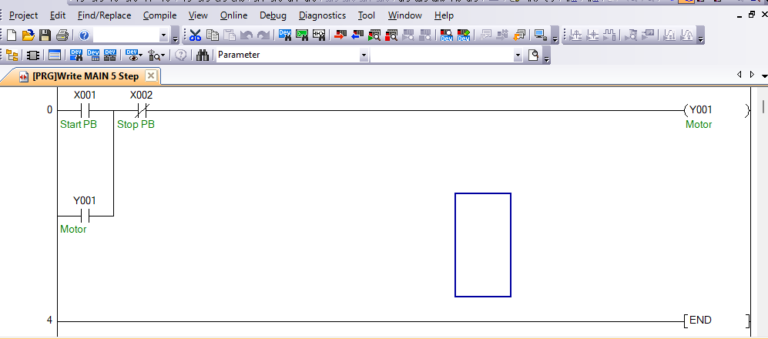

Imagine a simple ladder logic rung where:

- A selector switch activates the timer.

- The TON timer is configured with:

- Timer Tag:

Timer1 - Preset (PRE): 100 (for a 10‑second delay)

- Time Base: 0.1 seconds

- Timer Tag:

- Once the timer’s accumulated value (ACC) reaches 100, the output (e.g., conveyor motor start) is activated.

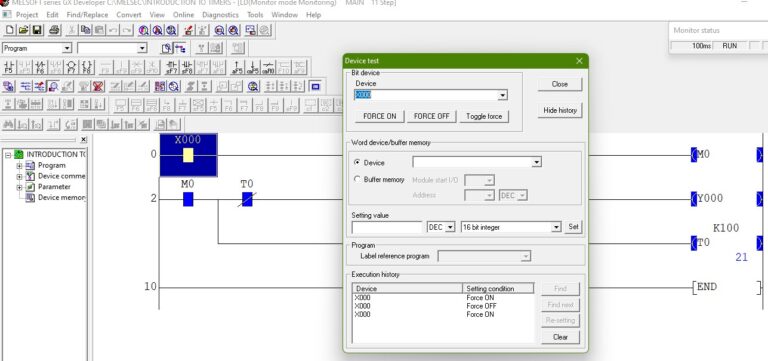

A ladder logic with a TON timer, labels for Timer1, PRE (K100), ACC(100 in blue), and an output Y001.

Real‑World Application: Conveyor Startup Delay

Scenario

Consider a conveyor system that should only start moving once the start button has been held for 10 seconds. This delay allows for all safety checks and ensures that the system is stable before the conveyor begins moving.

Implementation

-

Input Signal:

The start button (or a safety sensor) energizes the timer when pressed. -

Timer Operation:

- The TON timer (

Timer1) begins counting. - The accumulated value increases until it reaches the preset of 10,000.

- Once the 10‑second delay is reached, the timer’s done bit (.DN) activates, triggering the conveyor motor.

- The TON timer (

-

Benefits:

- Prevents premature startup

- Enhances safety by ensuring proper system checks

- Improves overall process reliability

Watch the Video from Bob Teaches Tech Channel

Bob Teaches Tech has an in‑depth PLC Timer Programming Tutorial that offers further insights into best practices and advanced troubleshooting strategies. Watch to learn more.

Troubleshooting & Best Practices

Common Issues and Solutions

-

Incorrect Preset Values:

Ensure that the time base is correctly configured so the preset value corresponds to the desired delay time. -

Timer Not Resetting Properly:

Verify that your logic includes a proper reset instruction when the input signal drops. -

Noisy Input Signals:

If the input signal fluctuates, consider implementing debounce routines to avoid false triggering of the timer.

Best Practices

- Double-Check Your Ladder Logic:

Validate all connections and ensure that the timer status bits are correctly monitored. - Simulate Your Program:

Always run simulations before deploying the logic to live machinery. - Keep Your Code Clean:

Use descriptive tags and comments to make maintenance easier.

On-Delay Timers in PLC Programming

On‑delay timers (TON) are an essential component of PLC programming. By understanding how to configure and troubleshoot TON timers, you can design more reliable and safer automation systems. This tutorial has covered everything from the basics of TON timers to a real‑world example of a conveyor startup delay, along with expert insights from Bob Teaches Tech.