Industrial Manipulators Are one of the essentials of pick-and-place operations in the industrial setup providing an easy and efficient way of moving items to different places. Learn how to program the AVIC International’s DLFA-JXS6 Industrial Manipulator using GX Work2 software.

DLFA-JXS6 Industrial Manipulator is one of AVIC International’s Training equipment that offers the training and the feel of the real deal. The machine or system is made of a mechanical structure of pneumatic pistons interconnected to form a robotic arm with 6 degrees of motion. The SCARA robotic arm is controlled by a set of directional control valves and a Mitsubishi Electric FX-32MR programmable logic controller (PLC).

Table of Contents

Getting Started With DLFA-JXS6 Industrial Manipulator

In order to get started with programming the robotic arm, we need to have the necessary hardware and software for the task. My assumption in this tutorial is that you have the basic knowledge of ladder logic programming and have worked with GX Works 2 programming software. If you are new to ladder logic programming, you can check out: Mitsubishi’s MELSEC series PLC Programming Basics (Part 1)- Absolute Beginner’s Guide To LD and IL – BTT Tech Articles

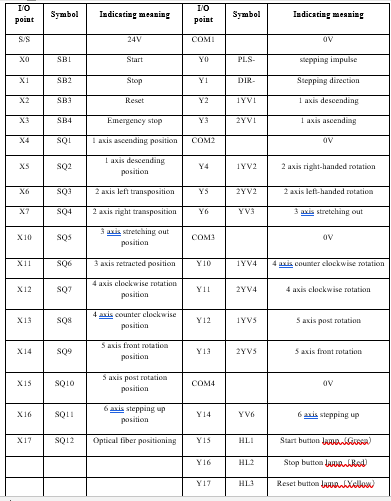

Creation of I/O Distribution Table

With everything set up and wiring done according to the datasheet, we need to create the I/O distribution table to show how each input and output of the system is connected. Below is the I/O distribution table that I created for this tutorial.

Step-by-Step Programming of DLFA-JXS6 Industrial Manipulator

Ladder logic programming structure may vary according to the personnel or the technician carrying out the programming, however, it is essential to note that the intended outputs should remain the same. For ease of programming, you can divide your programs into sub-groups that are attainable and can be easily debugged.

Another strategy you can use in programming is to program while in monitor write mode. This enables you to make live changes, seeing the output change while you program. This is a very effective technique where a large program or system is involved and there is limited time for project completion. Below are some of the step-by-step program breakdowns we took while developing the ladder logic program.

Button Group Control Program

Button groups host 4 push buttons, start, reset, stop, and E-stop, that are essential for the control and operation of the industrial manipulator. The E- stop, otherwise known as the emergency stop is used to cut off power from the system immediately stopping the operation. The reset button puts the arm in its initial position ready to start. While the start button starts the pick and place operation of the manipulator, the stop button stops the operation at any given point.

Cylinder Operation Program

Each cylinder is an independent and sequential action that can is controlled by independent solenoid-actuated directional control valves (DCV). The sequence is a complex process that is programmed based on the conditions of the magnetic reed switches found in each cylinder of the industrial manipulator.

To fully understand the programming process of the cylinder operation, you can follow along with the video as you refer to the I/O distribution table for a better picture of how each motion is articulated.

Testing And Debugging

The testing and debugging process is the steps in which we ensure the functionality of the system is made optimal by removing any form of error or adding some improvements to the system. It is therefore crucial that this process is carried out for the optimal performance of the system.

Programming AVIC International's DLFA-JXS6 Industrial Manipulator

Programming the DLFA-JXS6 Industrial Manipulator can be challenging if you are a beginner, however, it is not the toughest thing in the world of automation. This is because, with constant practice on ladder logic reasoning, you can come up with exemplary programs that fit the needs of any system.

Happy programming!

Want to test your theoretical skills and understanding of ladder logic programming? Check out our 15 Best PLC Programming Questions and Answers

Download the Ladder Logic Program For The DLFA-JXS6 Industrial Manipulator here with the zip extraction password as bobteachestech.com

Also, watch: The Maintenance And Repair of Automatic Production Line Training Device